We should make it clear at first that a foil container is after all a piece of disposable tableware which has a limit. And a key feature of aluminium is relatively soft and stretchable, it’s what makes it an ideal metal to convert.

Yet, there are still points to take.When we use a foil platter, we count on it to lift sandwiches and scones without bending itself; a takeaway foil container should be solid in hand to prevent shape changing and sauce pouring out; and a pie dish should be handled without having to support its burning bottom. A high quality foil container should has its job done hassle-free.

But what exactly makes the quality high? There are some key factors:

1. The gauge or weight. These are two different measurements but actually a same thing – different weights come from differently thick aluminium foils. Think about printing paper – the thicker the tougher. But weight isn’t everything. Let’s move on.

2. The embossing design. A reasonable embossing design can achieve the same strength of a heavier, less designed foil container. The renowned British foil container supplier i2r is an expert of it by their Ultra smoothwall range. We’ve changed the embossing for our major products for the same purpose as well. With more and smaller triangular sections on the bottom, the containers are more solid than those which are different.

Our old (left) and new (right) moulds of 7” round dish. The latter one’s embossing is visually making the dish tougher.

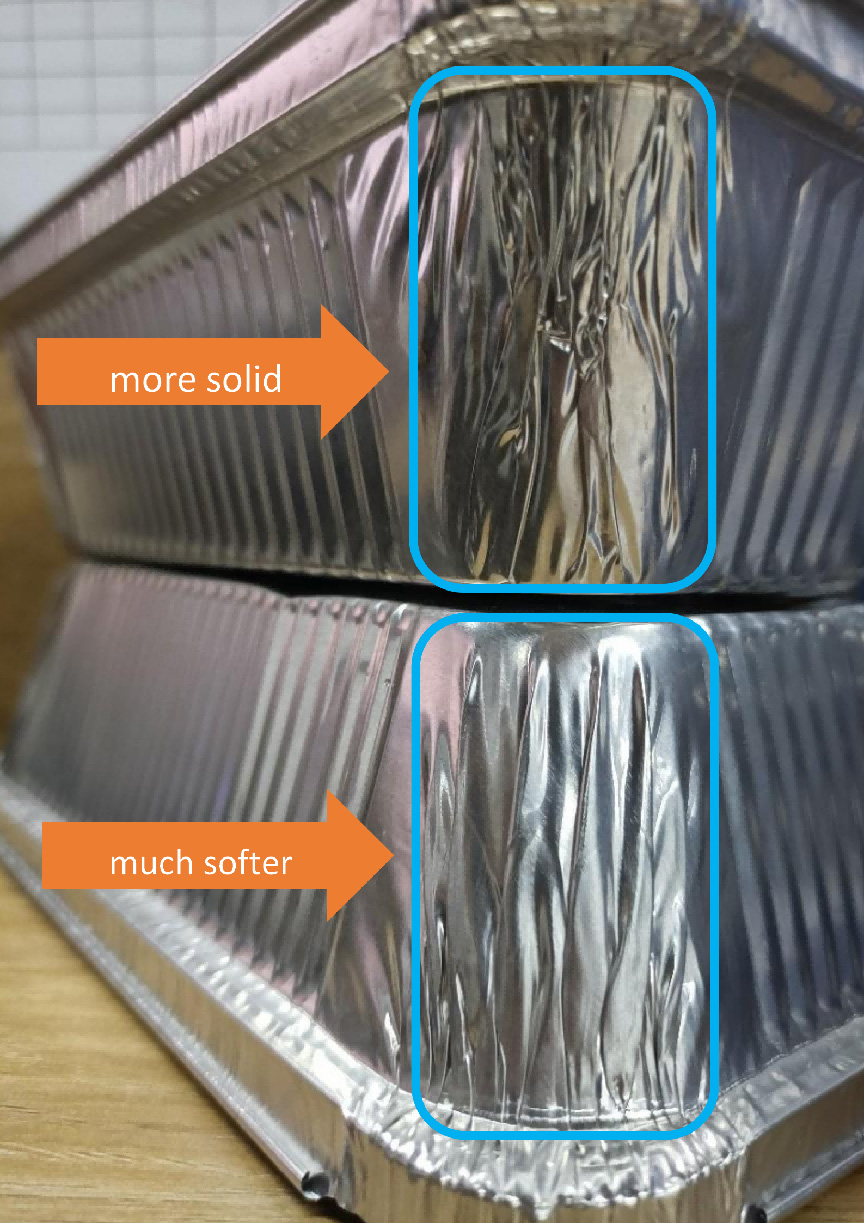

3. The corner wrinkles. This part is particularly for the wrinklewall containers. Check the corners carefully, you’ll figure out the differences – are the wrinkles folded tight, thick and top-to-bottom through? These hidden features determine the strength a lot.

Innovation is always in our vein and we value our clients and the environment. With better details we get to make the quality high while reducing the weight, by which to lower our clients costs and our carbon footprint.